To improve air quality in Kaohsiung City and respond to the government's net-zero carbon reduction policy, China Steel Corporation launched the "First and Second Phase Coke Oven Replacement Project" in 2020, specifically the "Construction of Coke Ovens and Dry Quenching Equipment Phases 1, 2, and 3." This project utilizes advanced bottom-spray recirculating combustion coke ovens, coupled with high-efficiency dry quenching equipment, which enhances waste heat recovery and reduces emissions. Upon completion, it is projected to reduce particulate matter emissions by 41 metric tons, volatile organic compound (VOC) emissions by 73 metric tons, and carbon dioxide emissions by approximately 145,000 metric tons annually, while also increasing annual power generation by 273 million kWh.

The new first and second stage coke ovens are not only more energy-efficient and environmentally friendly, but also feature four major model systems developed and introduced in terms of intelligent planning: a coal blending and process factor prediction model for coke quality, a vehicle intelligent collision avoidance system, a furnace temperature control and diagnostic system, and intelligent AI-based feeding settings. This project was commissioned by Paul Wurth Italia S.p.A. to provide design and equipment procurement services for China Steel Corporation (CSC), while PECL was awarded by Paul Wurth Italia to provide detailed designs for the coking ovens and coal chemical plant. The civil engineering design was completed in 2022, and the detailed design for the electromechanical piping was completed in 2024. Currently, Unit 1 has been completed and is undergoing trial operation, with Unit 2 scheduled for completion next year. Upon completion, the new coking ovens and coal chemical plant will improve coking efficiency, reduce air pollution emissions, and enhance energy recovery. PECL is very honored to have participated in this project and successfully completed it despite numerous difficulties related to space constraints and integration with the existing plant, making it one of Taiwan's leading consulting firms specializing in the engineering design of new coking ovens and coal chemical plants.

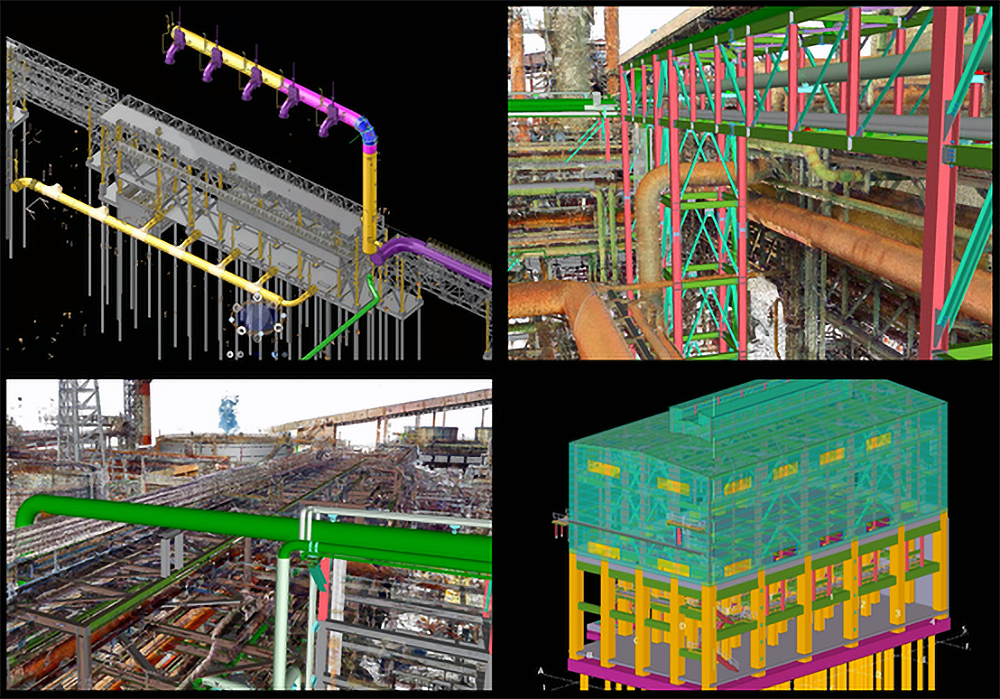

PECL has established a leading position in the application of Building Information Modeling (BIM). This project’s design was carried out 100% using 3D models for review and drawing production. The PECL team has extensive experience working in a 3D environment and is capable of developing comprehensive BIM and 3D execution plans along with related specifications.

During the design phase, a complete model review process was established, including 30%, 60%, and 90% model review meetings. These meetings allowed designers, owners, contractors, and subcontractors to gain an intuitive understanding of the design, clarify issues, and confirm details. This approach not only reduced rework and communication gaps but also accelerated the entire design process.

The adoption of a fully 3D approach simplified traditional errors and waste caused by repeated drafting and revisions of 2D drawings, while also helping to save time previously required for review and approval. By generating drawings from BIM models, design consistency was ensured, enabling all stakeholders to collaborate on a unified information basis and eliminating errors and confusion caused by version discrepancies or inconsistent information.

In the construction phase, isometric fabrication drawings generated from the model ensured that highly complex process piping could be accurately and quickly prepared for material take-off and assembly in the plant.

The project also utilized 3D laser scanning technology to capture real-world data of the existing coal chemical area and convert this information into point clouds and other 3D models to create highly accurate site data. In the early design stage, combining point cloud technology with street-view photos and measurement functions enabled rapid and precise pipeline positioning and planning. After pipeline modeling, collision checks were performed by comparing the pipeline model with point cloud data to ensure the design closely matched actual site conditions. This not only improved the efficiency of connecting new and existing pipelines but also reduced the risk of clashes and interference, thereby ensuring successful on-site execution.